Arrow Energy: Comprehensive Monitoring and Measurement Solutions

At Arrow Energy, we provide state-of-the-art monitoring and measurement devices designed to enhance operational efficiency, safety, and system reliability. From precision pressure gauges to advanced conductivity and TDS meters, our solutions empower industries to maintain optimal performance and ensure environmental compliance. Here’s a glimpse of the cutting-edge tools we offer:

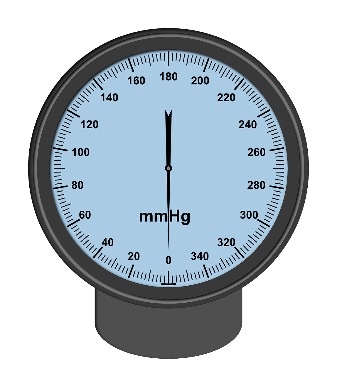

Pressure gauge

Features

- Accurate Monitoring of steam, feedwater, oil, gas, and draft pressure.

- Versatile Applications for various pressure ranges and industrial settings.

- Durable Construction for long-term reliability.

Pressure guages are used to determine

- Steam Pressure

- Feedwater Pressure

- Oil Pressure

- Gas Pressure

- Draft Pressure

- Boiler temperature gauges

Pressure gage is commonly classified as three types as the following below:

- Bourdon pressure gage

The bourdon pressure gage is type pressure gage which has bourdon tube, it’s an oval cross section of hollow tube. The tube has two ends, open and close. Open end is connected to fluids either water or steam and close end is connected to mechanical linkage in gage pointer. When the pressure builds up, the bourdon tube will be straightened out.

- Bellow pressure gage

This type is commonly applied for the pressure under 30 psi.

- Spiral pressure gage

The spiral pressure gage is modification design from bourdon pressure gage type. It has spiral and long pressure sensing.

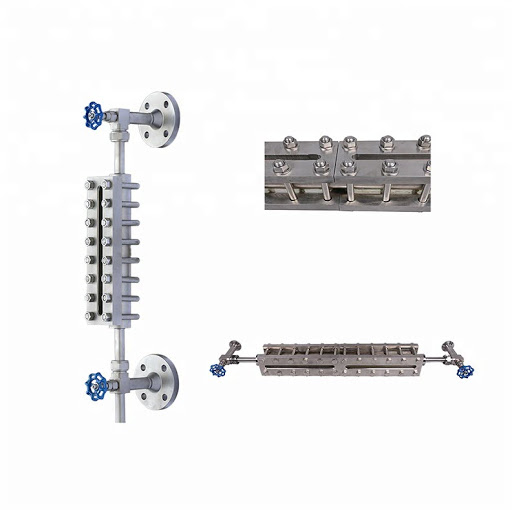

Gauge Glass

A gauge glass visually displays boiler water levels, preventing overheating and ensuring operational safety.

Features:

- Clear Visibility for precise water level readings.

- Protective Design with robust construction and shielding.

- High Compatibility with high-pressure boiler systems.

Level gauge

A level gauge indicates liquid levels in tanks using mechanical or float-based mechanisms, requiring no external power.

Features:

- Mechanical Operation for reliability and simplicity.

- High Visibility with clear reading options.

- Customizable Designs like tubular, float, and magnetic gauges.

Glass Type level Gauges

- Tubular Level Gauge (TTG)

- Reflex / Transparent Flat Glass Level Gauge (RFG & TFG)

- Transparent gauge

Float Type level Gauges

- Magnetic Level Gauge (MLG)

- Float and Board Gauge (FBG)

- Float & Tape Gauge (FTG)

- Float & Dial Gauge (FDG)

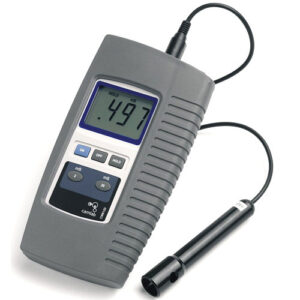

Conductivity Meter

A conductivity meter measures electrical conductivity in solutions, ensuring water quality and treatment efficiency.

Features:

- Precise Measurements for water and solution conductivity.

- Flexible Sensor Types, including contacting and electrodeless designs.

- Wide Application Range, in water treatment and environmental labs.

contacting-type conductivity meter

The contacting-type conductivity sensor usually consists of two electrodes, insulated from one another. The electrodes, typically 316 stainless steel, titanium-palladium alloy or graphite, are specifically sized and spaced to provide a known “cell constant.” Theoretically, a cell constant of 1.0 describes two electrodes, each being one square centimeter in area and spaced one centimeter apart.

Electrodeless type of conductivity meter

The electrodeless type of conductivity sensor operates by inducing an alternating current in a closed loop of solution and measuring its magnitude to determine conductivity. The conductivity meter drives Toroid A, which induces the alternating current in the solution. This AC signal flows in a closed loop through the sensor bore and surrounding solution. Toroid B senses the magnitude of the induced current, which is proportional to the conductance of the solution. This signal is processed in the meter to display the corresponding reading.

Total Dissolved Solid (TDS) Meter

A TDS meter evaluates organic and inorganic content in water, determining hardness and quality.

Features:

- Real-Time Monitoring of water quality and hardness levels.

- Scale Build-Up Detection to prevent system inefficiencies.

- Simple Operation for easy use in industrial and domestic applications.