At Arrow Energy, we provide a comprehensive range of auxiliary solutions, including valves, gaskets, and advanced fan systems, engineered to enhance performance, ensure reliability, and maintain system integrity across industrial applications.

Valve

A valve is a mechanical device designed to regulate, control, or direct the flow and pressure of fluids in a system. It operates by opening, closing, or partially obstructing pathways, ensuring precise control of fluid dynamics and pressure regulation.

Safety Valves

Safety valves are critical components that protect systems from overpressure by automatically releasing excess pressure when it exceeds safe limits. They ensure the safety and reliability of pressurized systems, commonly found in boilers and pressure vessels.

Key Features:

- New Valve Testing and Pop Testing.

- Specialized overhaul and testing of conventional, bellow, and pilot-operated valves.

- In-situ repair and hydraulic lift equipment for boiler safety valves.

Control Valves

Control valves manage the flow, pressure, and temperature within industrial processes by adjusting the valve opening based on system requirements. They enhance system efficiency and operational reliability.

Key Features:

- Overhaul and testing of control valves and actuators.

- Diagnostic monitoring tools for valve performance optimization.

- Workshop and on-site repair services for turnarounds.

Manual Valves

Manual valves, including gate, globe, check, ball, and butterfly types, control the flow manually and are essential for isolation and regulation in various industrial systems. They are durable and versatile.

Key Features:

- In-situ repair and testing services.

- On-line valve repair and high-pressure stuffing box repacking.

Gasket

Gaskets are elastomeric components designed to create a pressure-tight seal between two surfaces, preventing leaks and maintaining system integrity. Made from materials such as rubber, metal, cork, or foam, they are vital for reliable operation in various industrial applications.

Key Features:

- Material Versatility: Available in rubber, metal, cork, and foam for diverse applications.

- Leak Prevention: Ensures pressure-tight seals to prevent fluid or gas leaks.

- High Durability: Resistant to heat, pressure, and chemical exposure.

- Customizable Design: Tailored shapes and sizes for specific operational needs.

Forced Draft fans

Key Features:

- Adjustable air supply to maintain precise combustion efficiency.

- High-efficiency impellers for improved airflow performance.

- Robust construction to handle high temperatures and industrial environments.

- Energy-efficient motors for reduced operational costs.

Induced Draft Fans (ID Fans)

ID fans extract flue gases from the combustion chamber and guide them through the boiler assembly to the stack. They maintain system flow by overcoming pressure drops across boiler components, ensuring effective exhaust management.

Key Features:

- High-capacity airflow design for effective gas movement.

- Corrosion-resistant materials for durability in harsh environments.

- Advanced variable speed drives (VSD) for optimal energy consumption.

- Compact design with easy maintenance access.

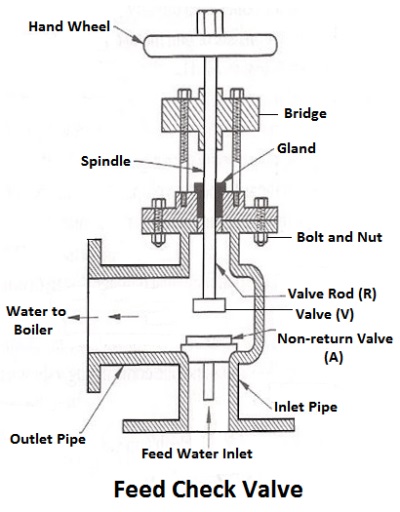

Feed Check Valve

Feed check valves control the flow of water from the feed pump to the boiler, preventing backflow when pump pressure is insufficient. Positioned at the boiler inlet, they ensure continuous water supply and system integrity.

Key Features:

- High-pressure sealing capability to prevent backflow.

- Durable construction with materials like stainless steel for extended lifespan.

- Compact design for easy installation and maintenance.

- Reliable performance under varying pressure conditions.