Collecting Plate and Discharge Electrode

Collecting Plates: Capturing the Charged Particles

- Electrostatic Attraction:

- The collecting plates are flat, metallic surfaces placed parallel to the discharge electrodes.

- These plates are oppositely charged (usually positive) relative to the charged particles.

- The charged particles are attracted to the plates and adhere to them due to electrostatic forces.

- Particle Accumulation:

- Over time, a layer of particulate matter accumulates on the plates.

- Regular cleaning prevents this buildup from reducing collection efficiency.

Discharge Electrodes: Ionizing the Particles

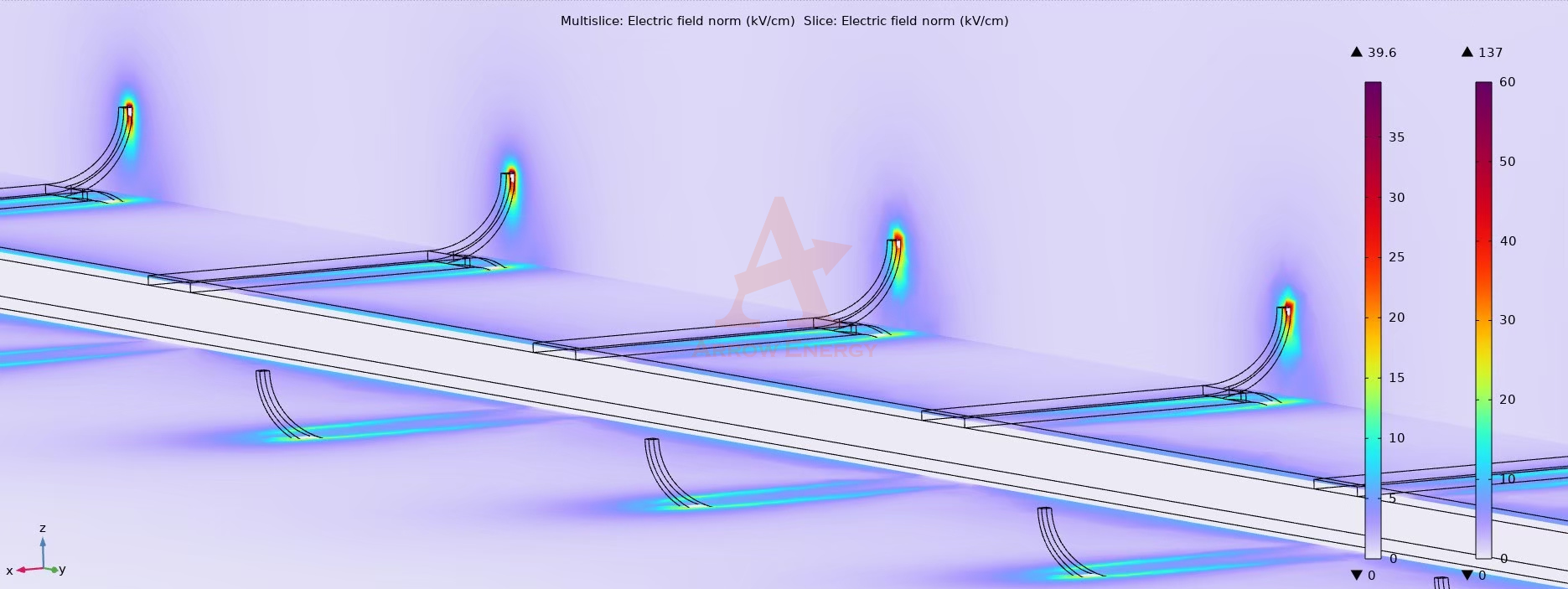

- Corona Discharge Generation:

- The discharge electrodes are thin, wire-like structures connected to a high-voltage power source.

- These electrodes produce a corona discharge, which generates a strong electric field and releases ions into the surrounding space.

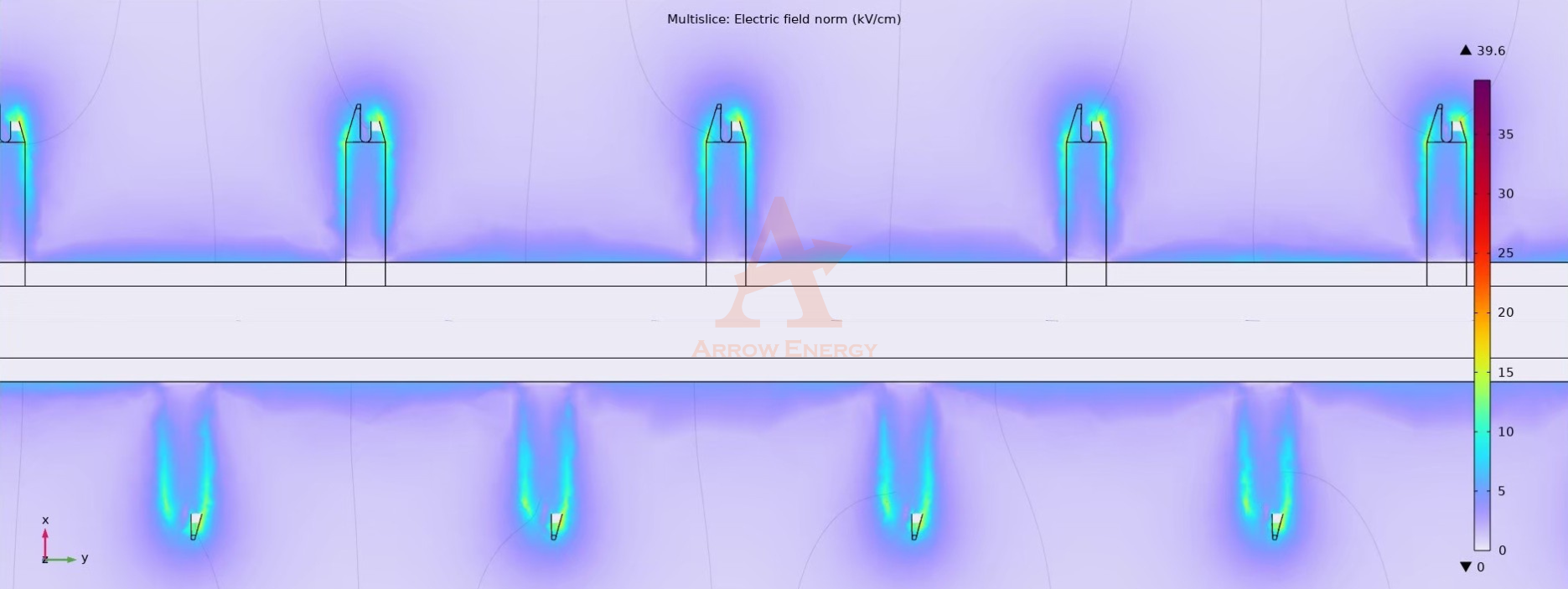

- Particle Ionization:

- When dust-laden gas flows through the ESP, the particles are exposed to the electric field.

- The particles interact with the ions, acquiring a negative or positive charge, depending on the electrode’s polarity.

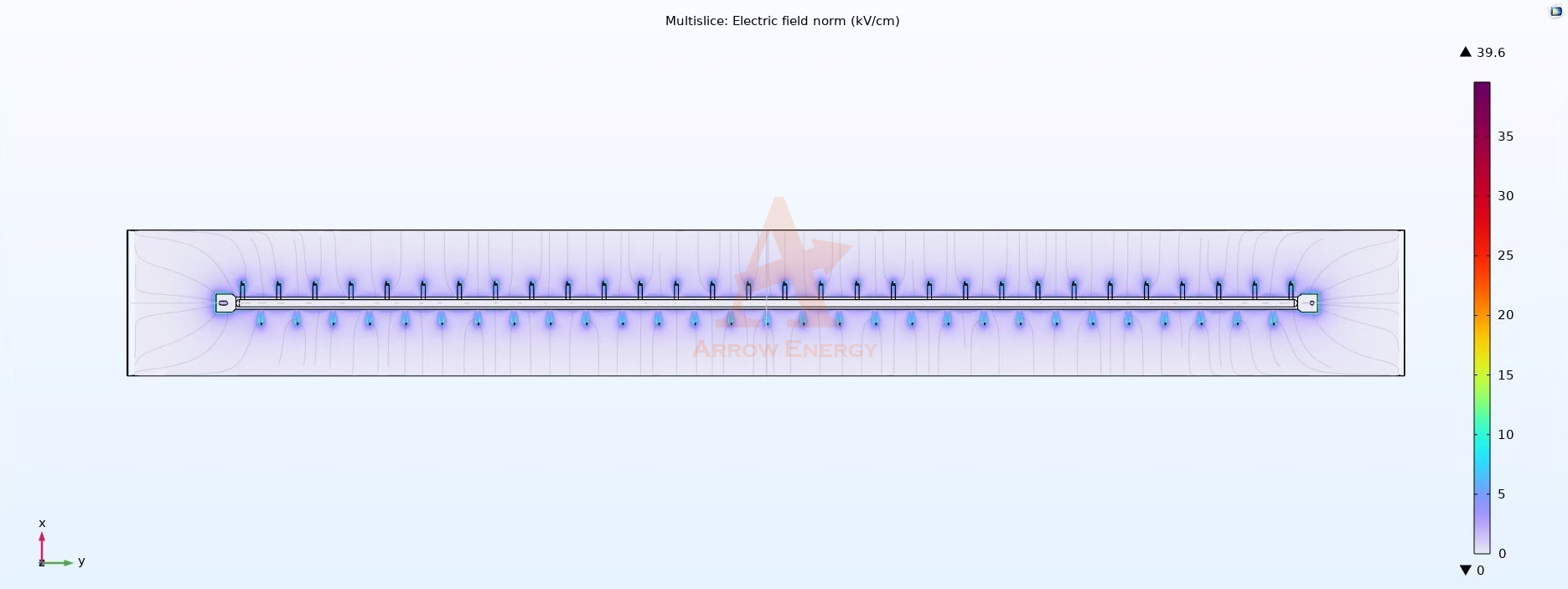

- Field Uniformity:

- The precise placement of discharge electrodes ensures the electrical field is evenly distributed, enabling consistent particle charging across the gas stream.

- High Efficiency: Plates and electrodes are engineered for superior particle capture.

- Durable Materials: Designed with high-alloy materials to withstand harsh operating conditions.

- Precision Charging: Ensures minimal energy loss and maximum collection efficiency.